About us

About us

s52 a.s. was established in 2000. The business name was inspired by the best-known product Slivovica (Plum Spirit) 52 %.

News

Read through the latest information about our news, activities and services that we have prepared for you.

History of distillery

The persuasive evidences of distillatory technology predecessor come from Ireland and Scotland already in 11th century.

Distillery

Technical term distillery originated from words “dis=separation” and “stillo=drop by drop”.

Genuine fruit distillate

Contains fruit distillate - alcohol distilled of a particular sort of fruit and water.

Genuine fruit distillate

Genuine fruit distillate excels among other distillates due to its unique taste and aromatic qualities. It disposes with a large scale of gentle fragrances that range from various sorts of fruits aromas to different romantic blends. With no exaggerations, it may be boldly said that it is a jewel among the distillates. There is a number of reasons supporting it, yet the structure of the pure fruit distillate itself makes the biggest difference.

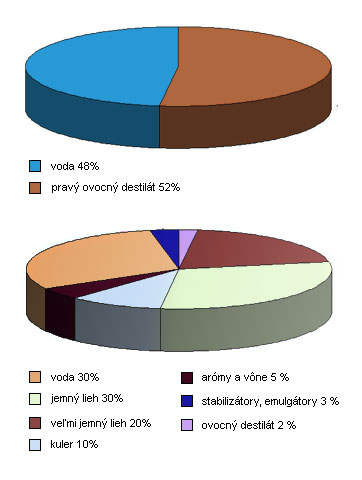

Genuine fruit distillate contains fruit distillate as an underlying structure, which is a mixture of an alcohol of a particular fruit and water. The pure fruit distillate emerges through process of fermentation of fruit that contains usually 50 % of alcohol. These two ingredients in final effect make up a rare product that stems from the nature. Under any circumstances, genuine fruit distillate does not contain any ingredients so typical for other categories of liquors (brandy) such as different types of alcohol, industrial aromas, syrups, stabilisers, or colorants. Genuine fruit distillate is never diluted with other type of alcohol.

Water is the other essential ingredient of genuine fruit distillate. Genuine fruit distillate contains after technological processing alcohol usually in the interval of 50 – 70 percent (depending on the particular sort of fruit). The remaining contain is made up of water. In order to reach the final 52 % percentage of alcohol in distillate the technique of dilution applies. Although this process may sound trivial, in reality it doe not comprise of simple refilling of certain volume of water. The reason behind this lies in a fact that both natural ingredients genuine distillate and water may form coagulum. Coagulum themselves do not conceive a health threat, as these are commonly present in fresh water. However, they cause esthetical flaws.

The problem with coagulum is in technological process avoided by the method of diluting the fruit distillate with de-mineralized water, which is the water purged of all minerals by electrical or osmotic technique. On the other hand de-mineralized water is not suitable for human body because of the missing minerals and salts, which are important for properly running of functions.

De-mineralized water in human organism creates hypotonic environment - the cells absorb the water for the purpose of balancing the concentration of salts. They enhance their size up to the limit. Crossing this limit may cause bursting of membrane. De-mineralized water demonstrates the water in imbalanced state. When it comes to contact with any material, it reacts aggressively. It “willingly accepts” (absorbs) all materials and substances that can be solved in water (hence comes the name “hungry water”) e.g. metals from pipes, softeners, and other toxic organic substances from hose distribution, plastic storages, etc. Thus, it can “de-activate” these substances, though containing no minerals substances.

The use of de-mineralized water in any products leads to reduction of the concentrations of electrolytes solved in body fluids. In the aftermath of impeding distribution of water among the cells, it may gradually evolve functional malfunctions of important human organs. The initial symptoms may include fatigue, overall weakness, and headache. The significant impediment of the concentration of electrolytes in human organism may even cause muscle convulsions or malfunctions of heart beat rhythm.

Due to these health risks s52, a.s. does not use in the process of final dilution the de-mineralized water but solely natural low mineralized water from flowing wells. The contain of minerals in this water meet the terms of the technological process of s52, a.s. . We, in s52 a.s., are convinced that the low mineralized water contributes to softening and determining of flavour of our genuine fruit spirits.

In discussion among specialists as well as laic public dominates a topic that explores whether it is more suitable to use in technological process of genuine fruit distillate direct warming or warming through duplicator (steam). Countless times repeated comparisons of distillates revealed that spirits produced by direct warming contains more flavour substances. Such distillates then dispose of more ample and smooth tastes. The fragrance has more fruitful character. Finally, these distillates are more qualitative than distillates produced by indirect warming.

Genuine fruit distillates mature in wooden barrel, in the environment of natural materials or at the presence of a sweet wooden stick or dry and fresh fruit.

It may appear that commercialization and globalization trends in segment of alcoholic drinks might drive aside the interest of customers in genuine fruit distillates. However, the figures support growing attractiveness of these products, which is well related to delicious flavours, decent aromas, and most of all the integrity of production itself.